One of the biggest challenges in modern retail and manufacturing is stock management. New trends, fluctuating demands and a constantly changing retail landscape all impact which products should be stocked and how many of each must be on the shelves and in the warehouse to maximize efficiency and reduce costs.

For some retailers, a safety stock calculation can simply be a gut-feeling, an educated guess at what they think is right. However, this isn’t recommended as it can cause issues with stock outs causing customer frustration and lost sales.

Using a safety stock formula helps you to take a data-driven approach to inventory management, maximizing sales and ultimately profits.

What is Safety Stock?

Before we dig into explaining how to use a safety stock formula, it’s useful to define what the term safety stock actually means.

Safety stock is simply extra inventory held by a retailer or a manufacturer in case demand increases unexpectedly. This means it’s additional stock above the desired inventory level that you would usually hold for day-to-day operations.

One of the main reasons that retailers and manufacturers implement a safety stock strategy is to prevent stockouts. Stockouts are usually caused by:

- Changes in consumer demand

- Incorrect stock forecasts

- Variability in lead times for raw materials

Trying to plan for these variables and maintain a target inventory level can be difficult. However, this is where a safety stock formula comes in.

Because there are multiple formulas for determining safety stock it can be a little complex, but this article will guide you through the various safety stock calculations and how each fits with the ordering process.

Why Do You Need a Safety Stock?

Although we know the consequences of not having enough stock, why do you need safety stock in the first place? The reason for having a safety stock strategy is to protect you against two external factors over which you have little to no control: demand uncertainty and lead time uncertainty.

1) Demand Uncertainty

Every retailer and manufacturer will have products that sell well all year round and products that fluctuate in demand. For example, products like razor blades are bought year round which makes it easier to define reorder quantities. If the supply and demand are consistent, you may not require large amounts of safety stock.

On the other hand, a product like desk fans is much more difficult to forecast. Generally you might sell more in the summer months, but how can you plan for a heatwave when demand is unexpectedly high? To cover an uncertainty like this you require much more safety stock of desk fans than you do for razor blades.

2) Lead Time Uncertainty

For manufacturers and companies that assemble products using different components, lead time is a critical factor to determine minimum inventory and safety stock requirements.

Just-in-Time manufacturing is used in the automobile industry and relies on parts arriving at the factory sometimes just hours before they need to be used on the production line. Production delays with suppliers and issues with customer delivery delays can have a huge impact, causing whole lines to be shut down.

This in turn can cause your own lead times to be affected. If you have deliveries arriving earlier or later than expected, a safety stock formula will help you to cover unexpected delays and demand fluctuation to maintain a consistent output.

Implement an IMS to gain greater inventory control, and less costly mis-ships.

Why Use the Safety Stock Formula?

Running out of stock has a direct impact on your day-to-day trading. Because of this, factoring in the cost of inventory stockout is important for understanding the role safety stock plays in the ordering process.

Some of the direct impacts on your business include:

- Loss of revenue

- Loss of gross profit

- Loss of customers

- Reduced market share

- Poor efficiency

- Strained supplier and retailer relationships

To put it simply, if you can’t meet the demand of your customers they will find someone else who will, be it online or a store down the street.

It’s clear that to keep everything running smoothly and to keep your customers happy a safety stock formula is essential. Spending time determining safety stock requirements will not only save you money, but it will also increase your efficiency on the shop floor and your storage space.

The overall result? Increased revenue and higher service level.

A quick note on service level:

Service level is the probability that the amount of inventory on hand during the lead time is sufficient to meet expected demand – that is, the probability that a stockout will not occur. The uncertainty of supply and demand makes it difficult to calculate the amount of stock needed to satisfy customers needs while avoiding stockouts.

4 Risks Related to Safety Stock

Ensuring that you have safety stock seems like a win-win, but it’s important to be aware of the risks related to safety stock. It’s possible to over-optimize stock levels, which isn’t always the best approach. Here are 4 common risks related to safety stock that you need to be aware of and factor into your safety stock calculation.

1. Setting Safety Stock to Zero

This is a common mistake made by people working in supply chain management. The aim is to reduce inventory levels and stock on-hand. Setting safety stock to zero will achieve this. However, the risk is that the service level will also decrease which ends up costing more than the cost of having extra inventory.

2. Using a Standard Safety Stock Formula

Businesses in different industries have different factors that impact their supply chain, and therefore their safety stock formula. Although there are common formulas that can be used, additional adjustments must be made for upstream failure, reorder period, and order quantity requirements.

3. Letting Safety Stock Decline as Supplier Lead Time Reduces

Safety stock helps to address variability in your supply chain and demand, so supplier lead time should not impact your safety stock, only your cycle stock. You should always safeguard your inventory by looking at the standard deviation time. For example, if your supplier has a lead time of five days and a standard deviation of two days, you need to ensure two days of safety stock (which is the variable).

4. Using Safety Stock to Prevent All Stock-outs

Stock-outs will always occur, no matter how much you want to prevent them. The safety stock formula is there to prevent the majority of stock-outs, but not all of them. Service level plays a key factor when calculating safety stock which is what you are trying to maintain. Finding the right balance between cost (of holding inventory) and service level is key. A 100% service level would mean you always have stock, which is a risk in itself and varies in demand.

Safety Stock with EOQ (Economic Order Quantity)

Safety stock used in conjunction with economic order quantity is a method that is usually used by companies making purchasing decisions rather than production decisions.

Economic Order Quantity (EOQ), also known as the Wilson formula, is a calculation used to determine the least costly number of units to order. The aim is to minimize the cost of ordering and holding stock, while still meeting demand and service level requirements.

The cost of ordering products is made up of the cost of placing your order, delivery, and transportation costs, and the cost of receiving the order. Holding costs consist of the financial costs of paying for stock in advance, warehousing and storage costs, and depreciation costs.

EOQ = economic order quantity in units

Q = estimated annual quantity used in units (can be found in the annual purchases budget)

O = estimated cost of placing one order

C = estimated cost to carry one unit in stock for one year

Ultimately the aim of EOQ is to have as little stock as possible while still being able to fulfill service demands. Clearly knowing what your safety stock requirements are is critical to achieving this fine balance.

Reorder Point Calculation

The final element to consider before we get into calculating safety stock using the safety stock formula is the reorder point calculation. This is relatively simple to understand and a really useful calculation to know.

Essentially your reorder point is the point at which you need to order a product or parts before you start using your safety stock. So, if you have a 15 day lead time you know that you will need to place your order 15 days in advance of your current stock running out.

In a perfect world, this will mean that you won’t ever need to use your safety stock but it’s highly unlikely this will happen. Safety stock is there to cover you in times of variability in demand and lead time. Safety stock will stop issues with your lead time and limit the impact of your service rate.

The reorder point calculator is simple:

Reorder Point = Safety Stock + Average Sales x Lead time

Calculating Safety Stock

When dealing with uncertainties and multiple variables, the best way to calculate safety stock is to use standard deviation to determine variations in supply and demand. The definition of standard deviation is a quantity calculated to indicate the extent of deviation for a group as a whole.

Which, in layman’s terms, means you:

- Find the average of a set of data

- Calculate the sum of the average and the data set

- Take the sum and divide it by the sample proportion to get the variance

- Add the variance to the average

- The sum amount will be your standard deviation.

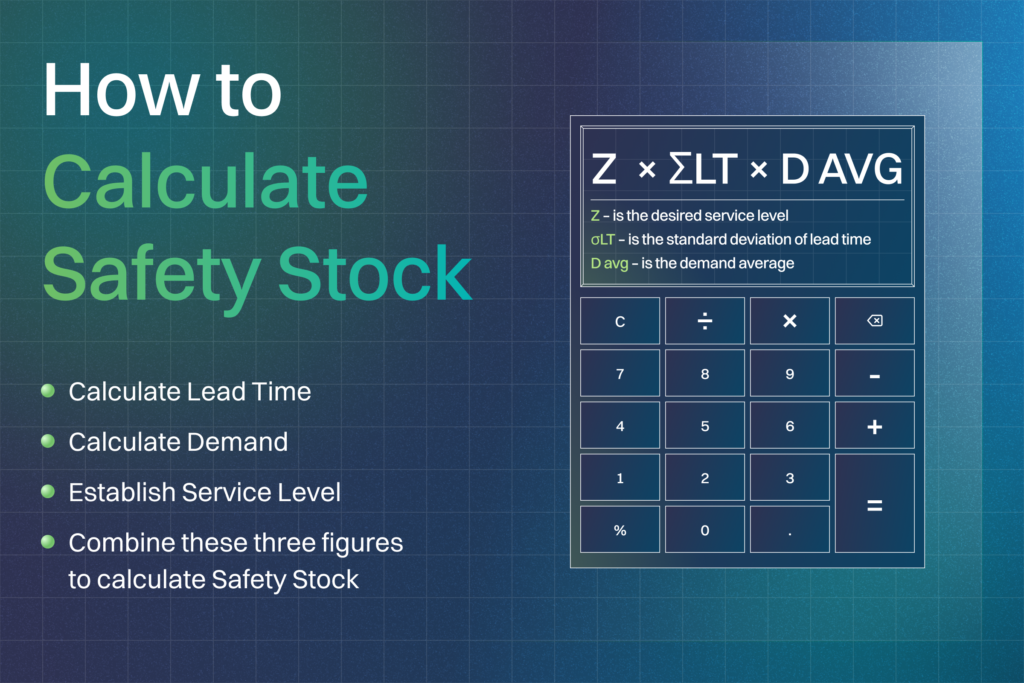

With this definition in mind, the formula for calculating safety stock is given by the equation.

Z × σLT × D avg

Z is the desired service level, σLT is the standard deviation of lead time, and D avg is the demand average.

Don’t be intimidated. The simplest method for calculating safety stock only requires a four-step process to calculate these variables.

1 | Calculate Lead Time

Quite simply, lead time is the time measured between starting and finishing a process. Factors within this process might include submitting a purchase requisition, approval time, emailing vendors, delivery time from the vendor, incoming inspection time, and the time it takes to put on the shelf.

If your lead time is constant, i.e. the total time to reorder and restock never changes, you can move onto the next stage in the safety stock calculator. However, this isn’t common so you need to calculate a standard variation of lead time to gain an accurate measurement for variable lead times.

The three key numbers that you need are the expected time, the actual time and the variance. The definition of each is:

- Expected time: The expected lead time of a product.

- Actual time: The real time it took to replenish each order.

- Variance: The difference between actual time and the expected time.

Here’s an example:

Positive numbers are the number of days over the expected time and negative numbers mean that the delivery arrived earlier than the expected time. With this information, we can find the standard deviation in lead time.

To find the standard deviation,

- Add up the variances, which in this example, equals 10: 5 + 3 + 5 + -1 + -2 = 10)

- Divide the sum of the variances by the sample portion (in this case, the lead time of the past 5 shipments): 10 ÷ 5 = 2

- Add this number to the average expected time: 6 + 2 = 8

Now you have the standard deviation for the lead time (σLT). We now know that the standard deviation for lead time is eight days which signifies the average amount of time it takes to restock, after taking into account the variability of actual time that orders have been received for the past five shipments. Eight days is also how long safety stock will have to cover until new product arrives.

2 | Calculate Demand

To calculate the demand average, begin by determining the time frame you want to account for. The time it takes between reorders is usually a good time frame.

If a product is reordered once every two weeks, then demand should be calculated in two-week increments. If the product is reordered once a month, the time frame will account for one month’s worth of sales. Let’s take a look at the table below:

In this example, the time frame is one month, broken down into weekly increments. Sales Volume highlights the number of units of the product that is sold each week.

To determine the demand average, simply take the sum of the total Sales Volume that month and divide it by the number of buying days. In this example, the sum of sales volume is 2550 units and the number of buying days is 30.

Demand average calculation: 2550 ÷ 30 = 85 units

3 | Establish Service Level

The final consideration when calculating safety stock is service level. The service level factor means deciding on the correct service level for a certain product by balancing inventory costs vs the cost of stock out. The higher the desired service level, the more safety stock is required.

The retail industry aims to maintain a typical service level of between 90% and 95%, although this does depend on the product being sold. As mentioned before, a higher service level is a risk as it increases the amount of stock being held.

To calculate your desired service level into a value that you can use in the safety stock calculation you will need to use a normal distribution chart. This will help you determine your service factor based on the service level you want to reach.

For example, If you are trying to maintain a service level of 90% your service factor will be 01.28. This number will serve as your service factor, or (Z), in the equation.

Continuing with this example, if you calculate for a 90% service level the equation looks more like; Safety Stock = 01.28 × 8 days × 85 units.

4 | CALCULATING SAFETY STOCK

Using the three figures you have calculated above, you can now complete the safety stock formula. To determine safety stock, simply multiply these three numbers.

01.28 x 8 days × 85 units = 870.4 units

Your inventory is now at 870.4 units, or 870 as you would round decimals to the nearest number.

This equation tells us that we need 870 units of safety stock on hand to meet the demand of sales over an average lead time of eight days, while maintaining a service level of 90%.

870 units can also be used as your reorder point, because we know that it’s only enough to last eight days. Once inventory reaches this level it’s time to place another order which decreases the possibility of a stockout.

Remember, there are more variables that go into the ordering process than just safety stock. Safety stock simply calculates the amount of extra stock that should be added to overall inventory and gives an indication on when to reorder.

Safety Stock Calculation: 6 Different Formulas

As we mentioned in the ‘Risks Related to Safety Stock’ section, using a standard formula can cause issues as it’s not always suitable for every industry. Because of these, here are six different safety stock formulas so you can choose the best method to suit your business.

Method 1: Basic Safety Stock Formula

The basic safety stock formula is the traditional method and takes into account the number of products you sell per day and the number of days of stock you want to hold at any one time.

For example, if you sell 100 products per day you want to have five days’ worth of safety stock. The calculation is 100 (products) x 5 (days worth of stock) giving you a safety stock of 500 units.

Method 2: Average – Max Formula

This method is commonly used but can be difficult if you have a particularly long lead time. Essentially you are aiming to calculate the average max units you need at any one time.

The calculation is: (maximum sale x maximum lead time) – (average sale x average lead time)

Using a 12 month period of data you can calculate your average daily sales. For example, 12,000 sales a year is 1,000 per month and 33 per day. You can see from the table that the maximum sales you had in one day was 40 in June. (1,200 / 30 days).

Out of the 10 deliveries you received for the year, the average lead time was 35 days with a max lead time of 40 days.

Now that you have the figures, simply put them into the average-max formula and you will have your safety stock calculation.

Method 3: Normal Distribution with Uncertainty About the Demand

This is a useful method when there are fluctuations in demand, but the lead time is relatively stable. We need two figures to use this formula.

Standard deviation of the demand x the root of the average delay

To calculate the standard deviation in demand you first need to calculate the average demand, which is the total monthly demand/number of months. Next, calculate the variability in demand by taking the square of each month’s difference, then the average of those squares together. The square root of the deviation is the standard deviation which represents the sales variability.

To determine lead time variability always use the same unit of measure as demand variability. This could be days, weeks, or months. To find lead time variability, calculate your average lead time then find the square root of the average of squared differences. You can then use these figures to calculate your safety stock.

Method 4: Normal Distribution with Uncertainty on the Lead Time

If you find that only your lead time is variable then you can use a formula that looks like this:

Z x average sales x the lead time deviation

As we explained previously, Z is the desired service level. We have explained how to calculate the other figures in the previous methods.

If your lead time variation is small, you will likely have a much lower safety stock because you know your supply will be fairly consistent. On the other hand, if your supply fluctuates dramatically you will require more safety stock to cover these longer lead time periods.

Method 5: Normal Distribution with Uncertainty On-demand and Independent Lead Time

This method is most effective for scenarios where there is a high degree of uncertainty about both demand and lead time. They both work independently of each other. Using the example of razor blades from earlier, the lead time does not impact the demand of the razor blades.

Because these factors are independent of each other and there are many variations the formula is more complex than others in this list. The safety stock formula looks like this:

Z * sqrt((Average LT*(Demand Standard Deviation) squared + (Average Sales * Lead Time Standard Deviation) squared)

This formula is incredibly useful when there is a great deal of uncertainty. It factors in both lead time uncertainty and sales uncertainty. For businesses operating with these unstable factors, safety stock is extremely important.

Method 6: Normal Distribution with Uncertainty on Demand and Dependent Lead Time

For situations where demand and lead time are linked, you might consider using this final formula. It could be that lead time causes uncertainty on demand or that demand is having an impact on lead times.

The calculation for this method is as follows:

Z * Demand Standard Deviation * Sqrt (Average LT) + Z * Average Sales * Lead Time Standard Deviation

Because variability can impact sales and vice versa, typically more safety stock is needed to account for these unpredictable variations.

Limits of the Normal Distribution for Your Safety Stock

Now that we have an idea of the six methods you can use to calculate safety stock, it’s important to know the limitations.

- It’s hard to predict buying behavior, so sales trends and buying habits may not sit perfectly within the mathematical bounds of these formulas. While safety stock will help you to prevent stockouts, they will still occur.

- The formulas used here do not take into account seasonal variations. Retailers and manufacturers impacted by seasonal buying trends may find it difficult to calculate safety stock levels.

- In a similar vein, a safety stock formula cannot account for extreme fluctuations in demand or lead time. So, if your lead times suddenly increases by six months it would not show within the normal distribution figure as it is a mean calculation and not an average.

- Should extreme cases have an impact on stock and sales, there’s a risk that decision makers may not trust the safety stock formulas at all and strive for high service levels. As we have seen, a service level of 100% would mean having infinite stock and is not a financially viable or safe option.

How to Choose the Right Formula for Your Safety Stock?

Before you choose the right formula for your safety stock you must first consider the quality and quantity of your data. As data is a critical element in all of these calculations, a solid and reliable data set to work from is critical. If not, your calculations could be inaccurate causing more issues than it solves.

Our advice for businesses that have low sales volumes of 100 or less is to use the second method in this list which is the “medium max” method. Essentially, you are aiming to calculate the average max units you need at any one time.

If your business experiences sales of 100-300 units per product per month, then it’s best to try method 3, normal distribution with uncertainty about the demand. This is a useful method when there are fluctuations in demand, but the lead time is relatively stable.

For businesses that experience a great deal of uncertainty, we recommend method 5, normal distribution with uncertainty on-demand and independent lead time. It’s useful in this scenario because it factors in both lead time uncertainty and sales uncertainty.

Conclusion

Safety stock management is a critical part of being a retailer and a manufacturer. It will help to reduce the chance of stock outs, which lead to inefficiency, unhappy customers, and ultimately, lost sales and reduced profits.

Using one of these six methods to calculate your safety stock will give you a data-driven figure for a target inventory level. Entrepreneurs and Operation Managers who understand their product and have data on past sales can expect higher inventory efficiency and higher revenue returns.

Life saver! I am writing a report for my boss on products that are shipped and ordered in high volume so we can prevent stockout incidents. This article was amazingly clear and pivotal to coding the report I am making. Thanks a million!

Very nicely written and delivered.

It will be great if the assumptions are made explicit. Was the lead time and demand assumed to be normally distributed in this case?